The Metra Electric Line is getting a major upgrade, but most customers will never know it. That’s because the new system works to prevent delays before they happen, making each ride on the line even more reliable.

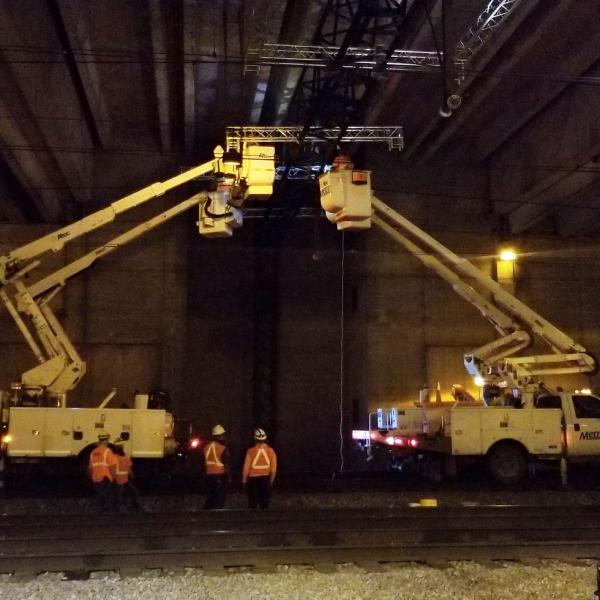

Crews in the mechanical and telecommunications departments have been installing an updated Automatic Pantograph Inspection System, also known as APIS, across all four tracks at McCormick Place. This new version of APIS uses thermal imagery, HD cameras and infrared strobes to provide highly detailed information about the condition of the pantographs, the contraptions on top of the trains that provide power to each trainset. Mechanical crews will monitor the information collected and, should an abnormality be observed, they will be able to repair the impending issue before it affects train movement.

Crews in the mechanical and telecommunications departments have been installing an updated Automatic Pantograph Inspection System, also known as APIS, across all four tracks at McCormick Place. This new version of APIS uses thermal imagery, HD cameras and infrared strobes to provide highly detailed information about the condition of the pantographs, the contraptions on top of the trains that provide power to each trainset. Mechanical crews will monitor the information collected and, should an abnormality be observed, they will be able to repair the impending issue before it affects train movement.

“It benefits the customer in two ways: On-time performance and cost,” said Adam Krogul, telecommunication supervisor on the Metra Electric Line. “This system will show us when a pantograph is worn, faulty or broken. It gives us an opportunity to change or repair it prior to it destroying the pantograph or the mainline wire. When the wire is damaged or down, it will create significant delays.”

The old APIS system, installed nearly two decades ago, covered only a few of the tracks south of Millennium Station and had far exceeded its useful life. The new system will not only cover all four tracks at McCormick Place, providing an eye on every Metra Electric and South Shore train that passes through, but the technology used will be far more advanced. The system will be capable of producing 3-D and thermal images to monitor the pantographs, and each train will be equipped with a unique RFID tag to identify it for repairs or adjustments, if necessary.

Installation of the new APIS started in January with the first track. After a brief interruption due to the coronavirus pandemic in March, crews have resumed work and plan to have the installation completed by early next year.